plug flow reactor example

The gradientless internal circulating reactor frequently used in measuring kinetics is actually a perfectly-mixed flow reactor which. This results in differential equations that need to be integrated to find the reactor conversion and outlet temperatures.

2 STEADY-STATE DESIGN OF CSTR SYSTEMS 31 21 Irreversible Single Reactant 31.

. Xie et al 2017. If all of the arguments are optional we can even call the function with no arguments. The concept of residence time originated in models of chemical reactors.

Since the plug flow operation of the biofilm reactor is favored the pump-driven continuous recirculation to create complete mixing of the bulk liquid applied by researchers Nie et al 2020. 142 Batch Reactor 21 143 Tubular Plug Flow Reactor 22 15 Heat Transfer in Reactors 24 16 Reactor ScaleUp 29 17 Conclusion 30 vii. Essentially no back mixing is assumed with plugs of fluid passing through the reactor.

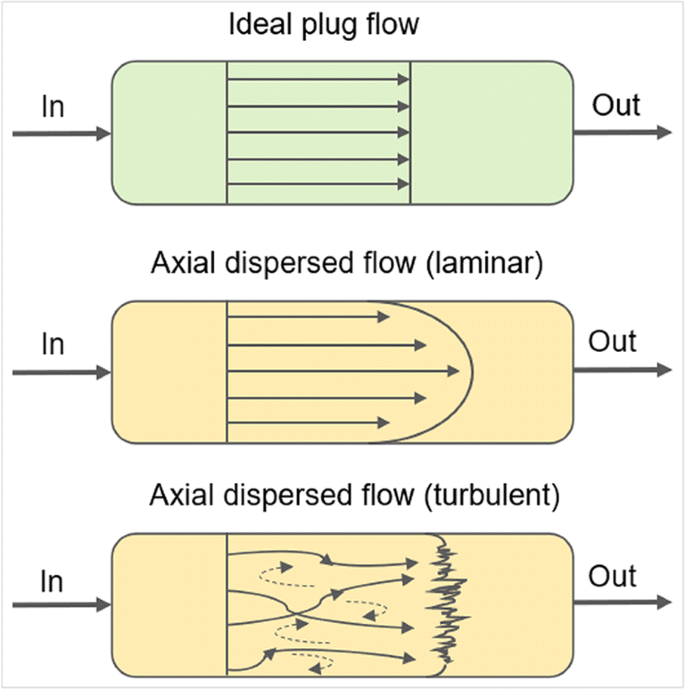

One of the most common reaction rates is the power law expression. In plug flow reactors the material entering into the reactor proceeds through the wastewater treatment plant without mixing with the material that has entered before or after. The first such model was an axial dispersion model by Irving Langmuir in 1908.

Proposed a pressure driven method of injecting a sample using. It is simple to control accurately the flow rate of reactants. The conditions are referred to as plug flow.

In the first call to the function we only define the argument a which is a mandatory positional argumentIn the second call we define a and n in the order they are defined in the functionFinally in the third call we define a as a positional argument and n as a keyword argument. Other models were developed such as the plug flow reactor model and the continuous stirred-tank reactor and the concept of a washout function representing the response to a. The plug flow model has many practical applications.

These reactors provide enough residence time for the reaction to take place with satisfactory conversion. However periodic flushing should be added to not. This received little attention for 45 years.

Xie et al 2018 might not be needed thus reducing the associated operational cost. This reduces the occurrence of side reactions and increases the yield of the desired product. CSTR continuous stirred tank reactor and the PFR plug flow reactor.

For example if a reactor has a volume of 20 m 3 and the feed rate of reactants is 40 m 3 h-1 the residence time is 20 m 3 40 m 3 h-1 05 h. Other simplifications used are. In the petroleum industry for example a significant fraction of our transportation.

One example is in the design of chemical reactors. In such reactors the reaction rate expression must be known determined. For example gas pressure is used to provide automatic generation of sequential flow known as a self-activated flow 2627.

Sizing A Plug Flow Reactor Pfr Youtube

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Isothermal Plug Flow Reactor Part 1 Youtube

Plug Flow Reactor With Ramped Flowrate Modelled As A Series Of Download Scientific Diagram

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram

1 4 Continuous Flow Reactors Elements Of Chemical Reaction Engineering Mole Balances Informit

Reactor Design And Selection For Effective Continuous Manufacturing Of Pharmaceuticals Springerlink

Mole Balance On A Plug Flow Reactor Youtube

Plug Flow Reactor Vapourtec Ltd

Variable Density Reaction In A Pfr Youtube

Deviation From An Ideal Flow Pattern Part 1 Petroleum Refining

Elements Of Chemical Reaction Engineering